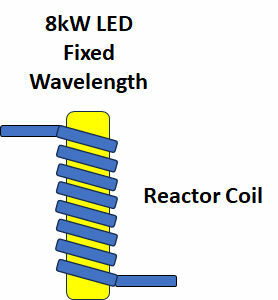

Photochemistry - Prototype development system

- A coiled, flow reactor surrounds an array of diodes at a fixed wavelength.

- High output lamps are used, driving the chemistry fast, giving high yields.

- Being a flow system, product is continually produced.

- Yields as high as 98-99% are frequently, easily achieved.

Photochemistry

Compared to batch operation, flow photochemistry has several advantages, including:

- Consistent light penetration.

- Exposure time is controlled.

- Temperature control is more precise.

- Product continuously passes through the system maintaining optimal conditions.

- Flow Photochemistry produces:

- Higher yields with better selectivity, faster.

- Reduced waste.

- Easier purification.

- Free Radical reactions have modest power requirements.

- Stoichiometric chemistry requires require high power.

- High power LED’s with specific frequency for high quantum efficiency – best solution.

- High power halogen and metal halide lamps offer broad spectrum, and high power 300W – 2kW.

- We now have an 8kW LED system available.

- Low pressure UV lamps – lower power but emission at specific wavelengths.

- Generally designed to meet the requirements of individual projects.

Photochemistry System

- Example photochemistry system, built in-house.

- First Generation System

- Using an 8kW lamp, this generates 1.5 tonnes annually if put to continuous use.

Development and Commercial Systems

- In addition to development, we supply a number of commercial machine options.

- We have a one, a two and a four tube option.

- The two tube option has demonstrated commercial scale at 1.5 tonnes per annum output, the 4 tube option is capable of 3 tonnes per annum.

- Each tube is powered by a 4kw LED light source.

- Therefore the commercial machines are sized as 4, 8 and 16kw.

- The commercial systems will be backed up by a development system.

- This approach has been demonstrated on several commercial projects to date.